How To Repair A Iphone Xr Screen

-

Power off your iPhone before beginning disassembly.

-

Remove the two half-dozen.seven mm-long pentalobe screws at the bottom edge of the iPhone.

-

If your iPhone has a croaky screen, go on further breakage independent and prevent bodily impairment during your repair by taping over the glass.

-

Lay overlapping strips of packing tape over the iPhone's display until the whole face up is covered.

-

If the cleaved glass makes it difficult to get a suction cup to stick in the side by side few steps, attempt folding a stiff piece of tape (such as duct tape) into a handle and lifting the brandish with that instead.

-

Use a hairdryer or heat gun, or prepare an iOpener and apply it to the lower edge of the iPhone for about a infinitesimal in club to soften up the adhesive underneath.

-

If the plastic depth judge is fastened at the center of the iSclack, remove it now—it'south not needed for larger phones like the iPhone XR.

-

Position the suction cups near the bottom edge of the iPhone—i on the front, and ane on the dorsum.

-

Press both suction cups firmly into place.

-

Hold onto your iPhone securely and close the handle of the iSclack to slightly separate the screen from the rear case of the phone.

-

Insert an opening pick into the gap under the display on the lower edge of the iPhone.

-

Skip the next 2 steps and proceed to step 8.

-

If y'all're using a single suction handle, apply it to the bottom edge of the telephone, while avoiding the curved portion of the glass.

-

Pull up on the suction cup with firm, constant pressure level to create a slight gap between the front panel and rear case.

-

Insert an opening pick into the gap.

-

Slide the opening pick around the lower left corner and upward the left edge of the iPhone, slicing through the adhesive holding the display in place.

-

Re-insert your pick at the bottom border of the iPhone, and slide it upwards the correct side to continue separating the adhesive.

-

Slide the opening pick effectually the tiptop corner of the brandish, while gently pulling or wiggling the display downwards in the management of the Lightning port.

-

Slide the pick to the opposite corner and cut any remaining agglutinative securing the brandish.

-

Pull on the modest nub on the suction cup to remove information technology from the front end console.

-

If y'all used an iSclack and it's nevertheless affixed to the iPhone, remove information technology now.

-

Open the iPhone by swinging the display up from the left side, like the dorsum cover of a volume.

-

Lean the display against something to keep it propped up while you're working on the telephone.

-

Remove three 1.2 mm Y000 screws securing the battery connector cover bracket.

-

Remove the subclass.

-

Employ the point of a spudger to pry the battery connector direct up out of its socket.

-

Bend the connector slightly away from the logic board to prevent information technology from accidentally making contact with the socket and providing power to the telephone during your repair.

-

Remove the two 1.2 mm Y000 screws securing the display connector subclass.

-

Remove the subclass.

-

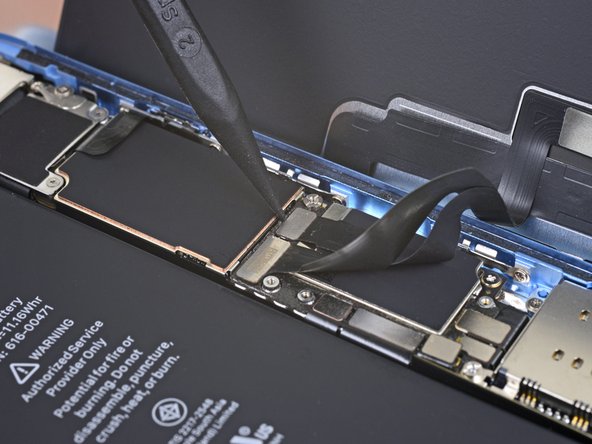

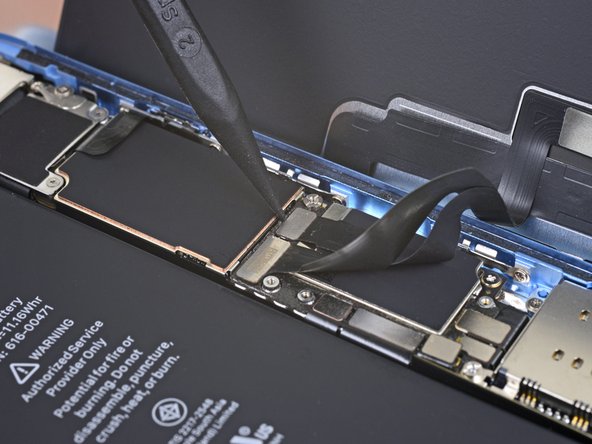

Use the tip of a spudger to pry upwardly and disconnect the digitizer cable.

-

Apply the tip of a spudger to disconnect the display cablevision connector.

-

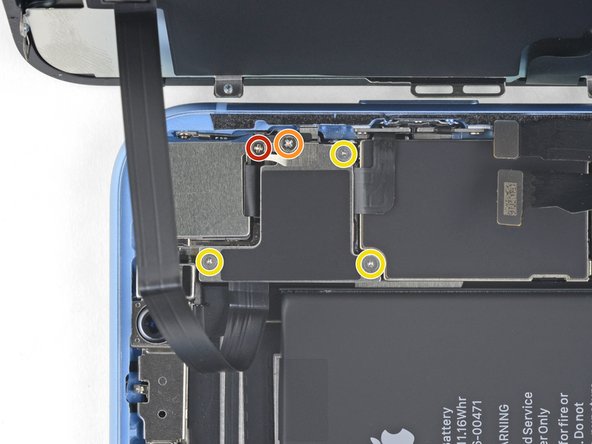

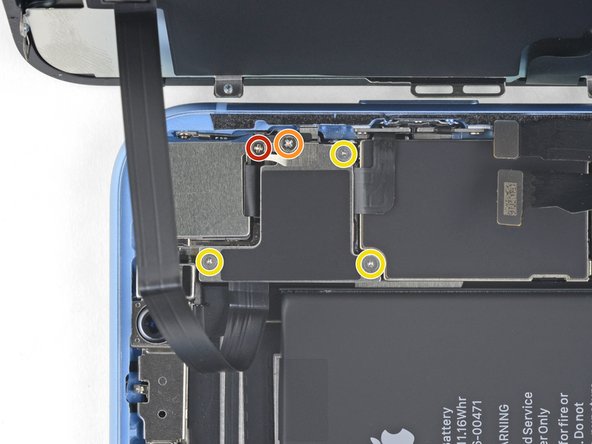

Remove the five screws securing the logic board connector bracket to the rear case:

-

One 1.3 mm Phillips #000 spiral

-

One ane.5 mm Phillips #000 screw

-

3 1.2 mm Y000 screws

-

Remove the subclass.

-

Apply the tip of a spudger to pry the front sensor associates connector up from its socket.

-

Remove the display assembly.

-

Remove the four screws securing the speaker/sensor assembly to the back of the display:

-

Two 1.6 mm Phillips screws

-

One 2.3 mm Phillips screw

-

One 1.ii mm Y000 screw

-

Using tweezers, gently flip the speaker assembly over—down and away from the peak edge of the brandish.

-

Use a hairdryer, a heat gun, or a heated iOpener applied to the tiptop front of the display for about a minute, in society to soften the adhesive securing the sensors.

-

Carefully slide the flat edge of a spudger underneath the flex cable below the microphone.

-

Twist gently to split up the microphone, while being careful non to strain or damage the flex cablevision.

-

If needed, apply the point of the spudger to end separating the microphone from its notch in the front panel. If the microphone remains hard to separate, utilise more heat.

-

Working left to right, slide an opening choice below the flex cable and underneath the proximity sensor + overflowing illuminator module.

-

Gently wiggle and lift to separate the module from its notch in the front panel.

-

Apply tweezers to slide the small bracket straight up and off of the ambient lite sensor.

-

Use tweezers to wiggle the ambient low-cal sensor and elevator it from its notch in the display.

-

If yous successfully removed the entire ambience light sensor, as shown in the first photo, keep to the adjacent footstep below.

-

If the white diffuser strip is detached and remains embedded in the display, as shown in the second photo, you volition need to advisedly lever it out along the summit border using a thin blade or pry tool. Re-applying estrus get-go may make this job a bit easier.

-

Remove the earpiece speaker and front sensor assembly.

-

Proximity sensor

-

Flood illuminator

-

The module must be positioned then that these components are not obstructed by any adhesive.

Source: https://www.ifixit.com/Guide/iPhone+XR+Screen+Replacement/116036

0 Response to "How To Repair A Iphone Xr Screen"

Post a Comment